Process

Improvement Case Study

Door

Assembly Process

Plant Background

The problem setting is a small furniture plant that primarily manufactures case goods, such as entertainment centers. Operating for a single eight hour shift, the plant produces 150 to 200 cases each day. The plant makes approximately 30 unique case styles, and each case can be made from a variety of wood species including Oak, Cherry, Pine, etc. An example of one such case is shown below.

Production Process:

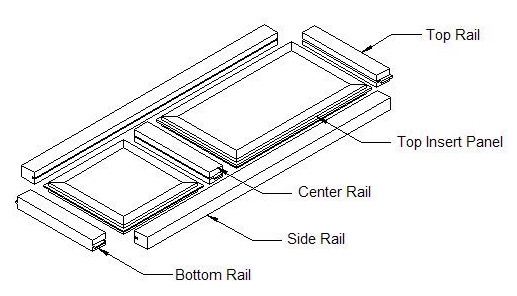

The production of a cabinet begins with the machining of a core of solid wood into a variety of machined parts, such as rails and moldings. In addition, front panels, shelving and side panels are cut from flat stock. This forming of parts takes place in the Machine Room. Also in the machine room, sub assemblies, such as doors, are assembled. The parts for a two panel door are shown below:

The completed parts are then transported in batches to the Cabinet Room. In the Cabinet Room, the parts and subassemblies are assembled and take on the form of a cabinet. A Cabinet Room build schedule determines how many of each case to assemble. This build schedule generates the schedules of what to machine in the Machine Room as well.

Once assembled, the case is placed on a continuously moving conveyor which transports the cabinet through the Finishing Room. In this room several operators use spray guns to apply paints, stains, and varnishes. The area also includes wiping and touch-up operations.

Upon completion, the cabinets are offloaded onto a roller conveyor for the final assembly and packing. In the Packing Room, activities such as inserting glass panels for doors, installing electrical power strips, and adding door knobs are performed. Finally, the case is wrapped in protective material and placed in a cardboard box for shipping.

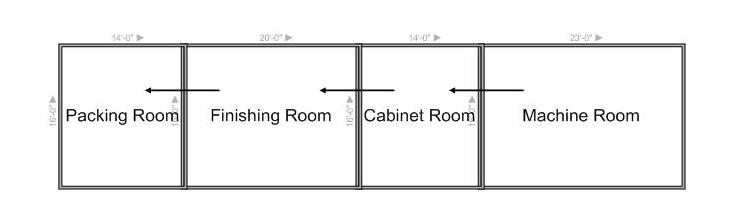

The diagram below shows the basic flow of parts between the different processing areas.