Tub Grinders

VIDEO: Tub Grinder - Model 2009 - DuraTech

Lesson 8: Waste Processing and Separation

Goals:

Read:

Assignments:

Separation at source (manual)

- Curbside (most successful)

- @3500 opoerations nation wide

- 40% mandatory

- Drop-off centers - ‘igloos’

- Cans, glass, plastics, newsprint

- Low participations

- Non-recyclables often discarded to avoid diposal costs

- Buy back centers (bottle bills, ADF)

- 90% of containers recycled in bottle bill states

- Bottle bill effect on curbside?

Separation at a materials recovery facility (MRF)

Clean MRF - Processing of separated materials (baling, crushing, etc.)

Dirty MRF - Separation of commingled MSW

*Both improve the quality of the recovered material (cleaning, separation of glass/plastics, contam removal, densification)

Size reduction

Tub Grinders

VIDEO: Tub Grinder - Model 2009 - DuraTech

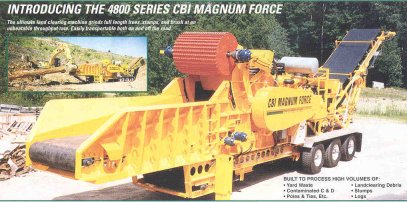

| Horizontal Grinders |

|

Size Separation

| Rotary Trommel Screens |

|

|

|

Mechanical Separation Techniques for Specific Materials

Ferrous metal - magnetism (most successful and efficient unit process)

Glass - froth flotation, optical separation tried in ‘70s but not efficient

Non-ferrous metals - flotation, electromagnetic eddy current, electrostatic separation tried, concentration and efficiency low

Plastics - no mechanical separation device in US source separation or hand picking, proprietary means used in Europe

Refuse Derived Fuel (RDF):