Lesson

12: MSW Landfills

Introduction

Read:

Definition:

engineered method of disposing of solid waste on land in a manner that protects

the environment

Operation:

spread refuse in thin layer, compact it, place daily cover (soil, ADC, geonet,

tarp, etc.) over waste at end of day

Compaction of Placed Waste

(Note: New Construction) |

Compaction of Daily Cover |

|

|

|

Equipment Used to Apply Foam as Daily Cover Material

|

|

|

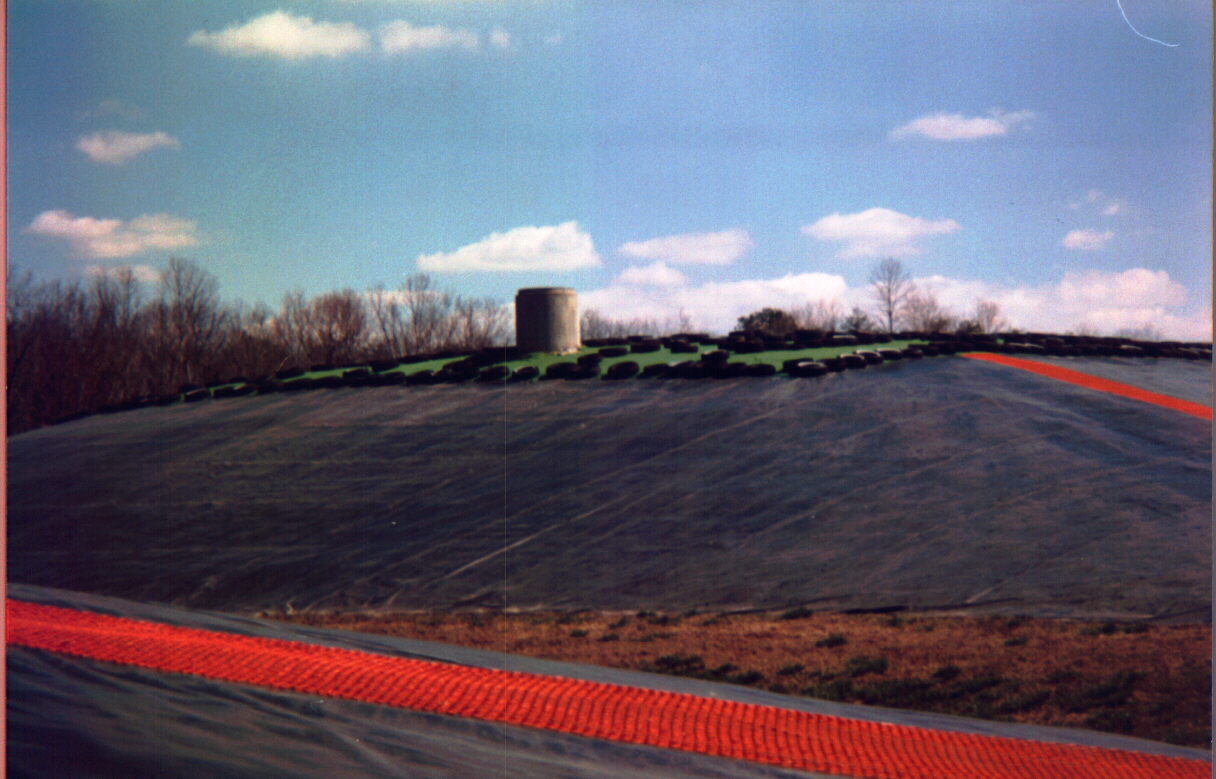

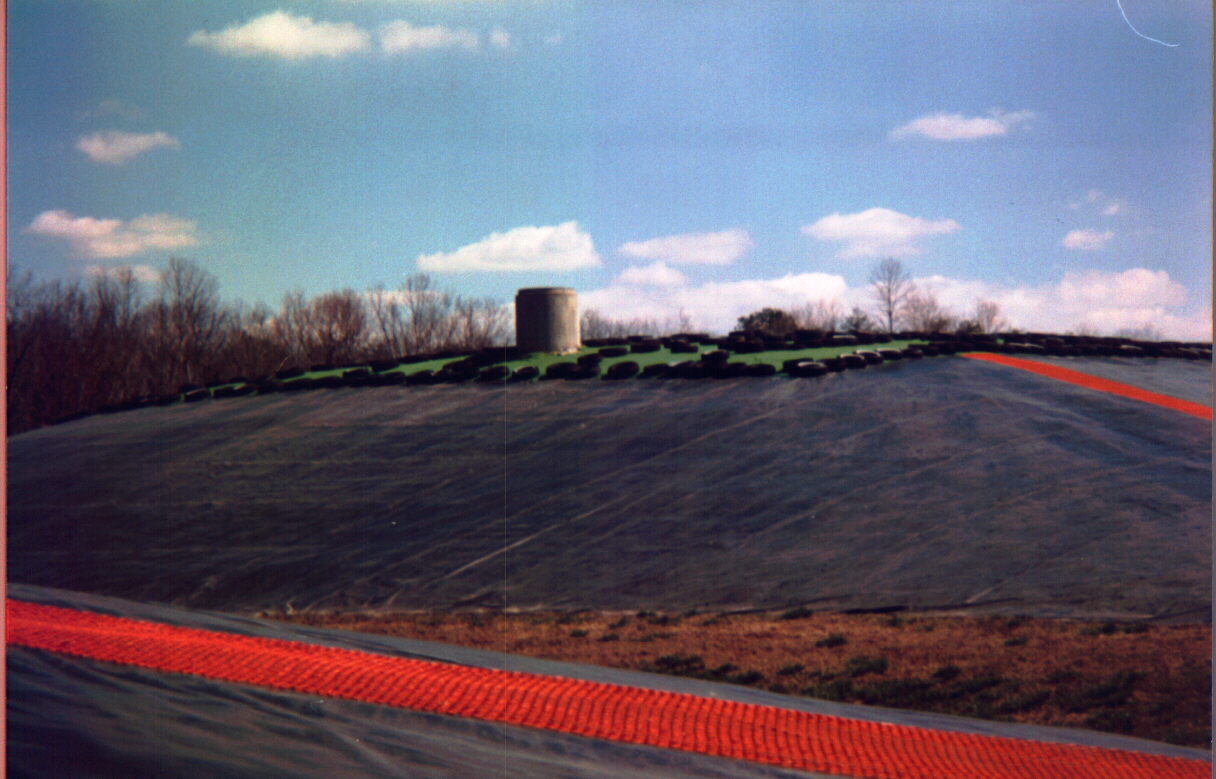

Older Landfill(Note Covered Waste Cells

and Recently Placed Waste at Right) |

|

Landfill Types

- Moisture

- Dry LF - keep waste dry to limit biological activity

- Wet LF - leachate recirculation used to moisten waste, bioreactor

- Use

- Municipal (sanitary)

- Hazardous

- Controlled LF - co-disposal

- Configuration

- Above ground LF - catch pan design - 3:1 or 4:1 slope

- Under ground LF - valley or depression used

- Special LF

- Conventional

- LF for milled (shredded) SW (35% greater in place density, daily cover

not required)

- Bale fills - waste compacted and baled prior to placement

- ”Mono-fill” LF - specialized cells - aesbestos, incinerator ash, anaerobic

decomp of yard waste

Construction Techniques

- Excavation method - ground water table (GWT) is distant from surface

- Trenches are excavated,L=100-400ft, W=15-25ft, D=10-15ft

- SW is dumped into trenches

- Tractors/compactors spread & compact refuse by pushing it up the working

face - multiple passes are made to maximize compaction

- Soil cover is placed on refuse, obtained from excavation

- Above ground method - used when excavation method is not feasible

- SW is unloaded and spread in long narrow strips (15-30in thick)

- Placement in strips is repeated multiple times until a predetermined cell

thickness is reached (usually 5-20 ft)

- Cover soil is applied (6-12in) at end of day (geotextiles, foams, ground

tires, compost, and other materials are often used)

- Embankment (working face) slope - 3:1 or 4:1

- Canyon/depression method

- Similar operational technique to Above Ground Method

- Used in areas where depressions (natural or artificial) exist, (canyons,

valleys, ravines, borrow pits)

Modern Landfills

- Leachate recirculation system (LRS)used to enhance biological activity

- Accelerate Lf stabilization

- Accelerate decomposition of organic SW

- In-situ storage and treatment facilities for leachate

- Increase biogass production

- Reduce liability, care, and post-closure costs

- Attenuation capacity against toxicity

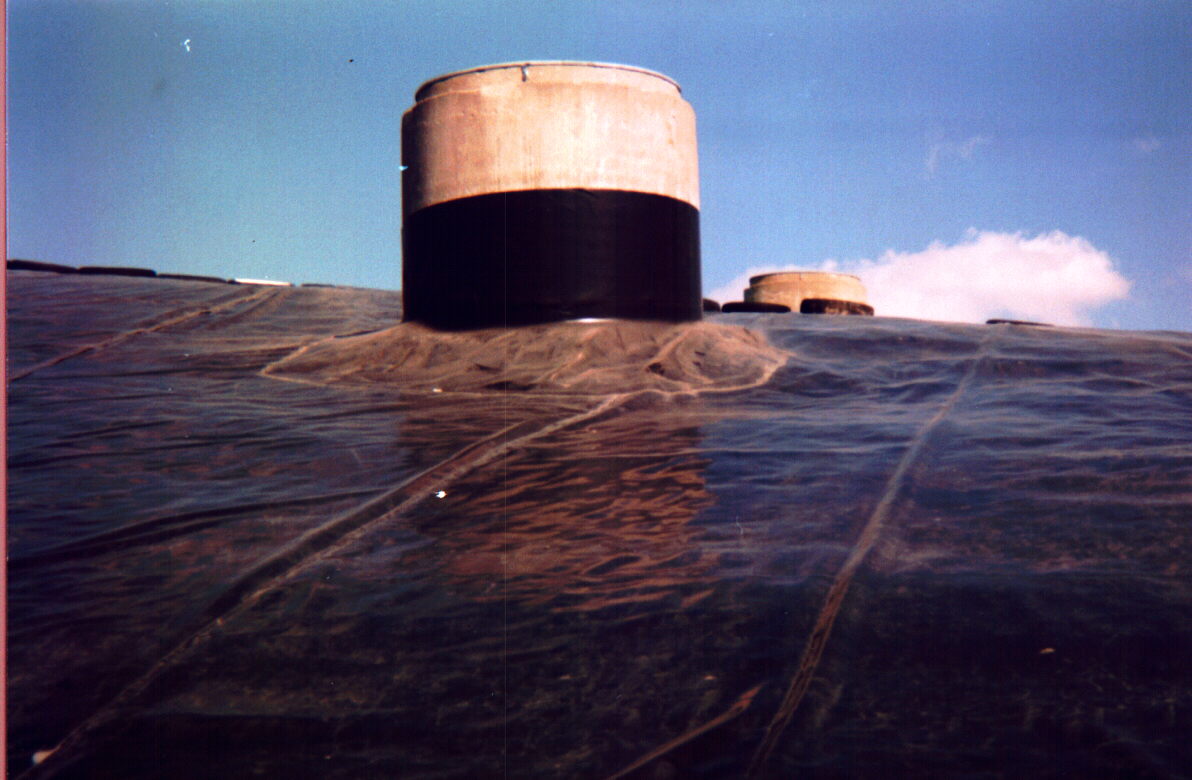

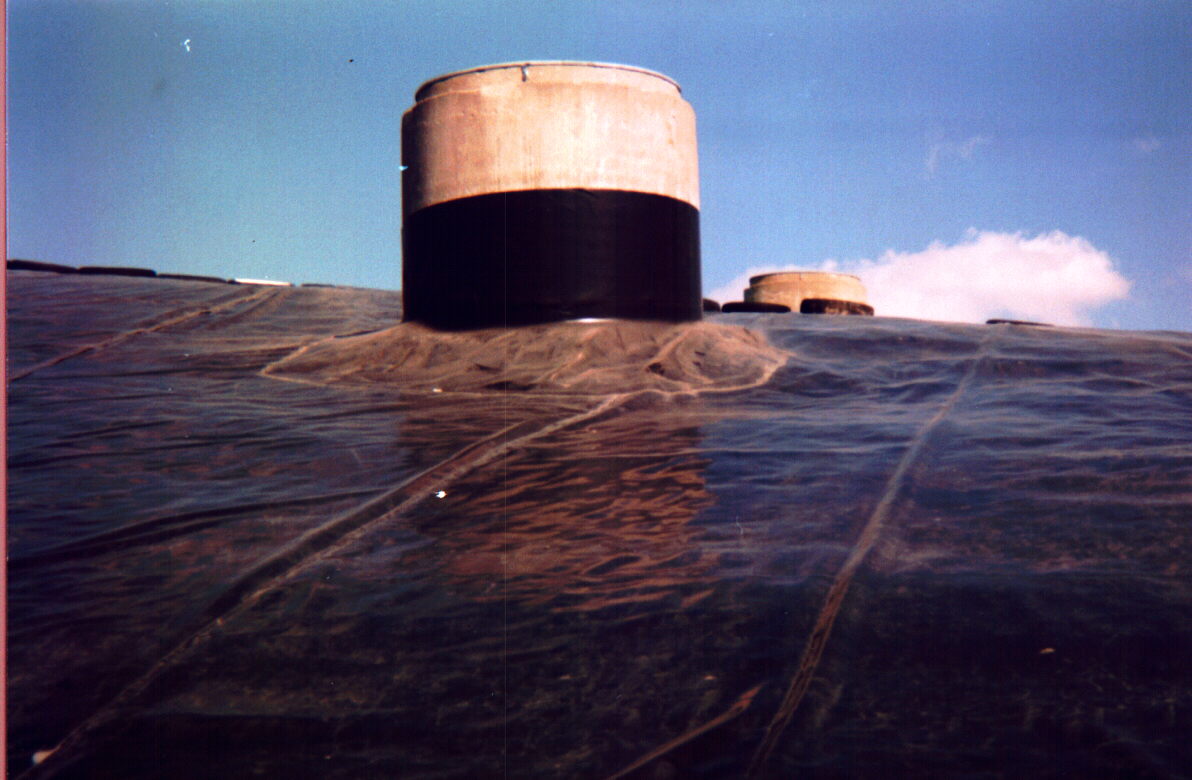

| Vertical Wells for Leachate Introduction |

Lysimeter at Delaware Solid Waste

Authority Note: Leachate Wells |

|

|

- Co-disposal with sewage sludge

- Moisture

- Micro-organisms

- Buffering capacity

- Nutrients

- Gas recovery systems - energy recovery

Site Selection

- Large enough to accomodate the SW needs of the area it serves (lifetime,

10 yrs)

- Compatible with the local SW management programs

- Site must protect public health, safety, welfare, & environment

- Minimize adverse impacts on surrounding area

- Minimeze adverse impacts on property value

- Minimize impacts on traffic flow

- Minimize potential for fire, spill, accidents

- Outside the 100 year flood plain

- Far from airports (birds) - 10,000’ from jet ports, 5,000’ from other airports

- Provide emergency response plan including notification, evacuation, &

containment procedures

Factors Affecting site selection

- Land availability

- Haul distance

- Impact on SW management program

- Soil conditions and topography

- Geological conditions - no LF within 200’ of fault or unstable area, seismic

activity

- Hydrologic conditions (surface and ground water) ----- leachate concerns

- Climatic conditions (rainfall and wind)

- Environmental and ecological conditions

- Public input and concerns - NIMBY, NIMTOO

- Potential use after closure

Define:

- leachate -

- LCRS (LCS) -

- LRS

- GCS -

- lifts -

- cells -

- cover -

- cap -

Page last updated April 5, 2017 by Dr.

McCreanor